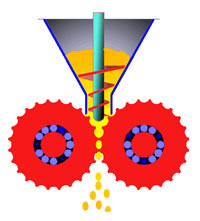

Working Principle

This DRG compactor is a dry extrusion granulator with counter rollers. Different dry powders are fed into the machine from top end, and then enter into the counter rollers after degassing and spirally pre-compacting. The great extrusion force generated by the counter rollers is used to create plastic deformation of materials, and then the materials are compacted into dense flake or bulk. The flakes are crushed, pelletized and screened to obtain the particles that meet the requirement of granularity. The pastille shapes of bulk materials are determined by the specially processed concave of roller surface, and after the pastilles are screened for the purpose of removing existing flash and powder, they can be packaged or stored directly. In addition, the extrusion force is adjustable according to the granulation requirement, and this is achieved by controlling the pressure of hydraulic cylinder.

Technical Parameters

| Model | Center Distance between Rollers (mm) | Transmission Power (kW) |

| DRG-240 | 240 | 7.5-15 |

| DRG-360 | 360 | 22-45 |

| DRG-460 | 460 | 37-60 |

| DRG-520 | 520 | 45-90 |

| DRG-600 | 600 | 55-200 |

| DRG-800 | 800 | 90-315 |

| DRG-1000 | 1000 | 160-560 |

|

|

Applications

Our compactor is suitable for different kinds of materials, such as pigment, detergent, catalyst, fertilizer, pesticide, oxide, strontium carbonate, bleaching powder, white carbon black, inorganic salt, chlorinated isocyanuric acid, particles filled in the capsule, etc. Recycled dust in industry is also applicable including lead dust, zinc dust, aluminum dust, dust filtration, grinding dust, dust of rotary kiln, dust in the iron foundry and others.

Features

1. This compactor has great operating flexibility and wide range of applicable materials, and the extrusion force can be adjusted by the hydraulic pressure.

2. The granules are formed through forced compaction by mechanical pressure, and wetting agent is not required. So, the purity is ensured.

3. Dry powder is directly used for granulation, and further drying process is unnecessary which makes our machine suitable for the improvement of existing production flow.

4. The process flow is simple and short, and it has the advantages of low energy consumption as well as large production capacity.

5. The granules obtained possess high strength, and the bulk density improvement is more obvious when compared with other granulation methods. Thus, our compactor is especially suitable for conditions that the bulk density is required to be increased.

We are an experienced compactor manufacturer and supplier in China. We provide various types of products such as drum sulphur granulator, die plate press / pellet mill, conveyor steel belt, and vibrating fluid bed dryer.

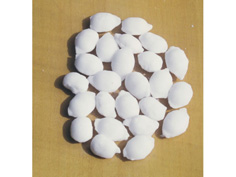

Sample

|

|

|

|

|

Related Names

Dry Pressing Granulator | Drying Equipment | DRG Rolls Axial Mill | Rotary Forging and Pressing Equipment