Working Principle

The rotary drum of this RDG drum sulphur granulator is equipped with several lifting plates. Meanwhile, molten liquid materials and water cooling pipe are set inside the drum, and some spray nozzles are distributed on the cooling pipe. When the drum rotates, the lifting plates continuously carry the powder or small particles on the bottom end of drum to the top end, and then the particles will fall down to form a continuous curtain of materials. On the other side of curtain, liquid material and cooling water are sprayed to the curtain from separated nozzles simultaneously. The atomized liquid material contacts with small granules, and the small granules are enlarged gradually. The atomized cooling water can rapidly cool and solidify the particles coated with liquid material.

The rotary drum of this granulator tilts down along the discharge end in axial direction, so the liquid material goes through three stages inside the drum which are seed particle (powder or small particle) generation, size enlarging as well as product forming, and then spherical particles that meet the requirements of granularity are obtained at the discharge end. On the other hand, the sprayed cooling water is converted into water vapor by the sensible heat of material and latent heat of solidification, then drained with off-gas by draught fan after dedusting treatment.

Rdg-machine

Specifications

| No. | Model | Production Capacity |

| 1 | RDG-8 | 8T/h |

| 2 | RDG-15 | 15T/h |

| 3 | RDG-30 | 30T/h |

Note

1. For sulphur, the available models have different production capacities including 8T/h, 16T/h, 22T/h, 30T/h, etc.

2. For other materials, the production capacity depends on the physical property.

Applications

In principle, this granulator is suitable for the materials that go through condensation-solidification-granulation process. These materials should have high melting point (softening point) as well as low liquid viscosity under molten condition, and they are insoluble in water or not hydrophilic. In addition, the most typical material is sulphur.

Features

1. The molten material contacts with cooling water directly which ensures high cooling efficiency, rapid solidification and large production capacity. For sulphur, the production capacity of single machine can be as large as 22T/h which equals to 3-4 sets of rotary steel belt type.

2. The granularity and size distribution of the solidified material can be regulated within a certain range, and this is realized by adjusting the material flow rate, cooling water flow rate, rotating speed of drum as well as tilted angle of drum. Usually, the size range is 2-10mm.

3. The atomized cooling water has a direct contact with particle surface, and the latent heat of vaporization of cooling water takes away the heat of materials. Thus, the material will be solidified fast, and the water consumption is very low. In addition, the circulating water treatment is not necessary.

4. The temperatures of different points inside the granulator are detected, and the flow rate of liquid material or cooling water is real-time controlled by the computer. In this way, the materials are rapidly cooled, and the water content is effectively prevented from getting too large.

5. The granulation starts with seed particle generation, then the particle size increases due to layer-by-layer spraying. Finally, the granule is solidified layer-by-layer. Thus, the granules obtained are compact. Compared with underwater granulation process, there are no pores inside our particles, and the water content can be lower than 0.4% while the water content of particles obtained by underwater granulation is over 2%. On the other hand, our granulator also shows better performance than the rotary steel belt granulator. The particles processed by our machine possess big bulk density, low brittleness as well as good fluidity, and the bulk density reaches up to 1.15-1.3. The bulk density for particles processed by rotary steel belt is only 1.0-1.1, and these particles are flat and fragile.

6. Our product also has the advantages of small floor area, little investment, little maintenance, low energy consumption, continuous and stable running, etc.

Our company is a professional drum sulphur granulator manufacturer and supplier in China. We offer a comprehensive range of products, including steel belt pastillator and flaker, screw extruder granulating machine, ploughshare mixing granulator, and more.

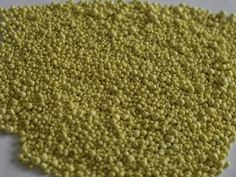

Sample

|

|

By October 2015, our company has sold 36 rotary-drum sulphur granulators to China and other countries.

Related Names

Sulfur Pelleting Machine | Rotary Drum Granulating Machine